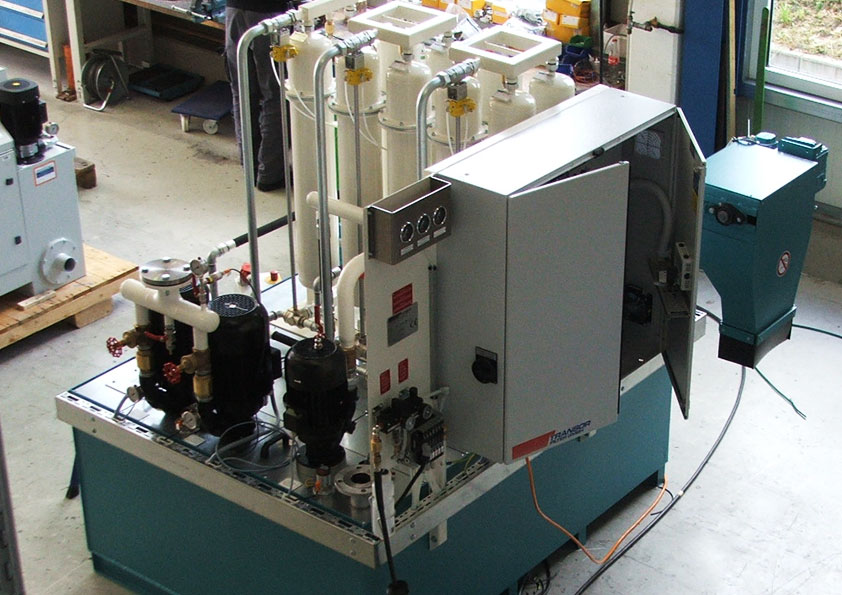

TCF individual units

Especially for single supply of coolant to 1 to 4 machines there are highly standardised constructions with capacities from 70-300 l/min.

The units are compatible with all types of known grinding machines. The removal of sludge material can be done manually or fully automatic with miniaturized drag conveyors.